Tungsten inert gas (TIG) welding is one of the most common methods used for metal fabrication today.

It’s a versatile technique that can be applied in many industries, such as construction, automotive manufacturing, shipbuilding, and more.

But at its core, this relatively simple process involves only basic hand tools like tongs, rods, spade bits, wire feeders, etc., which makes it easy to get started but challenging to master.

So, how long does it take to learn TIG welding? To become proficient at TIG welding, you typically need to practice for 150 hours if you already have some welding experience and fundamental knowledge.

However, about 3 months of TIG practice at welding school, 4 hours a day in the garage, is required to become halfway proficient enough to secure a job welding copper. Having stated that, two to three weeks should be sufficient to weld stainless and carbon pipes that are two inches thick.

The good news is, learning TIG welding isn’t impossible but there are several factors working against you. Here’s why:

Why Does It Take So Long to Learn TIG Welding?

When trying to learn TIG welding, there are six main challenges:

Let’s take a closer look at each one of these issues.

1. It Can Be Difficult to Concentrate

As with any skill or craft, even the simplest task becomes easier if your focus remains on what needs to be done.

Distraction Often Leads to Serious Mistakes

On top of being an important factor for success, concentration also helps to prevent mistakes from happening by keeping you focused on your work.

When TIG welding, however, distractions play a big role in stopping you from doing things right. For example, while practicing holding up shields during training sessions so that instructors can inspect them, students will often drop their masks accidentally.

Other times, they’ll have conversations with other people nearby who may distract them from what they’re supposed to do.

How to Improve Your Concentration When TIG Welding

2. Eye-Hand Coordination Takes Practice

Making eye contact with the tip of a rod or another piece of tungsten electrode is extremely important for successful welds. Unfortunately, it’s not something everyone naturally has experience with.

Most people were never taught how to properly hold and position objects correctly in order to achieve the best results possible. However, through trial and error, you can develop this ability over time.

Try viewing the area around you straight ahead, then turn 90 degrees clockwise and view it again. This should show you whether your vision lines up with your facial muscles, which allows you to identify potential areas that need improvement.

Practice Doesn’t Make Perfect. Practice Reduces the Imperfection

Ultimately, remember that just because you’ve been welding longer than others doesn’t mean you’re necessarily better at it yet!

Take every opportunity to ask questions and receive feedback from experienced teachers or mentors. By taking part in group activities, you can build confidence faster than if you tried to teach yourself independently.

3. Lack of TIG Welding Experience

Stick and MIG demand coordination, but you don’t need surgical hands to be successful with these techniques. Although having steady hands is ideal, slight movement can still result in some excellent beads being laid down.

On the contrary, TIG welding calls for not just smoother hand motions but also the use of two hands. You must feed the filler rod with your other hand while managing your travel speed and keeping a good arc length (the distance between the electrode and the steel).

The filler rod on their tungsten electrode frequently gets bumped by beginners who struggle with this. Before welding can proceed, the tungsten must be re-sharpened because when these two interact, it contaminates the metal. To get rid of all the impurity if the hump is too bad, you might need to trim your tungsten.

4. Lift Arc and Scratch Starts Can Be Challenging for Beginners

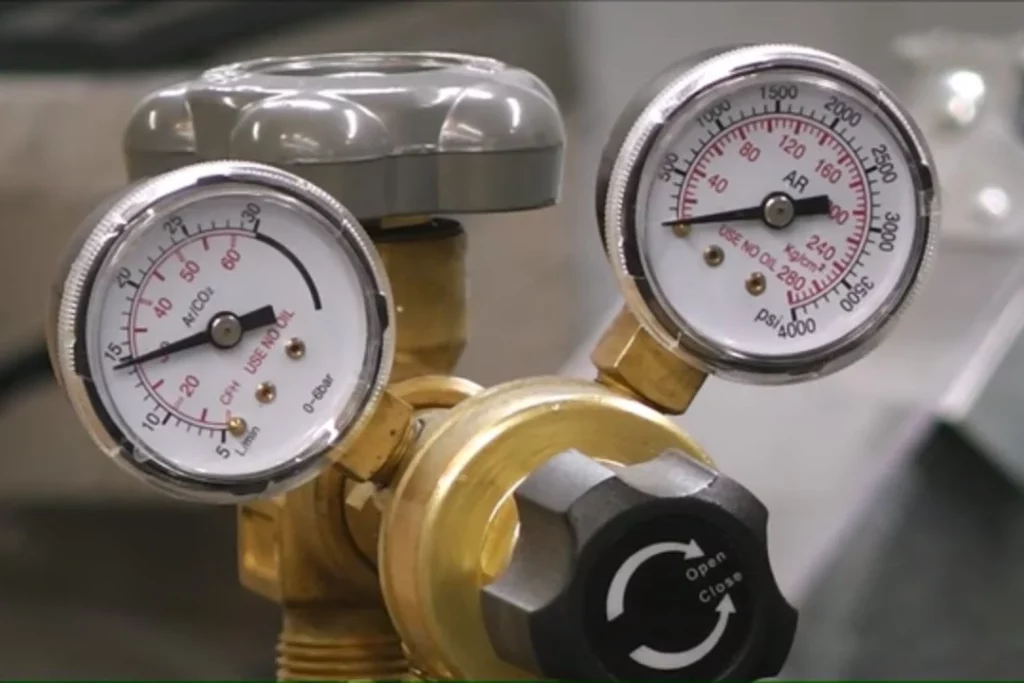

Usually, a foot pedal is used to perform TIG welding. By starting with a high frequency, this pedal starts the arc. The amount you press down determines how much amperage is produced. You can now tell where there is a challenge since all three of your limbs are functioning at once.

The so-called “lift arc” will undoubtedly be present on a lower-end machine that lacks high-frequency starting. This implies that the arc must be started by quickly touching your tungsten to your steel and lifting your arm. This is rather simple to master even though it may somewhat taint your tungsten.

“Scratch start” is the term used to describe the most basic TIG arc start. Since there is no involvement of a foot pedal, your amperage will stay the same. The arc can be started by simply scratching the tungsten on the steel (much like lighting a match).

Although high-frequency starters are the easiest for beginners to use, lifting and scratching are also excellent start-up techniques. Lift arc and scratch starts can be challenging for beginners accustomed to high frequency, but you can get the hang of it quite quickly.

It will become second nature and you won’t have to think about it as much after a lot of practice with this challenging TIG technique. While some beginners will advance more quickly than others, quality welds will appear if you practice regularly.

5. Your Training Might Not Cover All Aspects of the Job

Some jobs require very specific skills that aren’t covered well enough in school classes. An electrician would probably benefit much more from a class specifically designed for them than a general welding course would.

While it does provide some knowledge, a professional instructor could fill in gaps that a student wouldn’t pick up otherwise.

Even though it’s not mandatory to complete formal education before starting a career, it’s still recommended to gain additional qualifications before diving into a new line of work.

Just because you don’t have certification doesn’t mean you shouldn’t pursue further studies, especially considering the high demand for skilled workers in certain fields.

6. Avoiding Contamination Seems Elusive At First

The major issue for newcomers will be tungsten contamination. Frequently returning to the bench grinder to re-sharpen might make beginners quite angry.

This is because tungsten becomes tainted when it touches the steel while welding. For beginners who are determining the proper arc length, this is extremely typical. By bumping your tungsten, you can sour a good puddle.

Also, very clean metal is needed for TIG welding. Before striking an arc, you must prepare the steel by removing mill scale, rust, and grease. Impurities cannot be penetrated by a TIG arc due to its unique properties.

TIG just isn’t able to do this, but stick and MIG welds can tolerate and even cut through mill scale. An appropriate stainless steel brushing is required before aluminum TIG welding, eliminating grease and oil in the process.

Although using an angle grinder isn’t difficult to master, beginners will still need to learn the correct metal preparation technique before starting TIG welding.

How to Become Good at TIG Welding

Now that you understand some of the challenges involved in learning TIG welding, here are some tips to help you overcome them and succeed in becoming a great TIG welder.

1. Get Started Early

Like anything worthwhile, learning to weld starts early. There are plenty of ways to begin developing your abilities. Beginner-level tasks include making small repairs, cleaning equipment, and preparing materials for welding.

Once you feel comfortable completing those steps, move on to larger projects. Find a mentor and become familiar with safety procedures. Don’t rush into situations unprepared, since that could lead to costly accidents in the future.

2. Learn From Experienced Teachers and Mentors

Taking part in workshops and seminars hosted by professionals is highly beneficial. Instructors usually come equipped with lots of useful information, including helpful resources, step-by-step instructions, and project examples.

They can answer any concerns you have and offer guidance whenever needed. At the same time, it’s smart to seek advice from multiple sources to find the answers to tough questions that arise along the way.

Before attending a workshop or seminar, research its history and reputation thoroughly. Check reviews posted online and read customer testimonials. Ask previous attendees about their experiences and opinions regarding the event.

3. Read TIG Welding Books, Magazines, and Articles

Reading informative articles about various topics related to welding can boost your interest.

These subjects range from the basics, such as understanding electricity, to more technical techniques like MIG welding, stick welding, oxy-fuel cutting, plasma cutters, and more.

Books and publications written by experts are ideal for beginners. Keep in mind that although they can provide valuable insight, information found in textbooks cannot replace practical instruction.

Instead, choose a book that matches your current stage and provides detailed explanations of concepts and processes.

4. Experiment With New Equipment and Methods

Since you won’t always have access to the latest welding technologies, it’s wise to experiment with older ones once in a while. Doing so gives you a chance to explore your personal preferences and determine which kind works best for you.

You can even test out ideas learned elsewhere on existing pieces of equipment. Afterward, compare notes with other welders to discover what worked well for them. Remember, nothing replaces getting real-world experience with your own projects.

5. Feel Free to Ask Questions

Whether it’s at a local store or factory, finding qualified personnel willing to discuss your unique situation is crucial. Make sure you pose relevant questions about your goals, expectations, and budget.

Many businesses will gladly assist customers who approach them with inquiries. Be open to suggestions provided by salespeople and technicians, and take notes of what is said.

Afterward, review what you wrote down, and consider seeking more information.

6. Take Part In Group Activities

Joining groups dedicated to improving your skills is an excellent option. Meetup.com is a popular platform where users create communities centered around their interests.

Groups usually consist of individuals with similar hobbies and professions. Meeting people with shared passions can enhance communication and collaboration opportunities.

Additionally, forming friendships and partnerships with fellow enthusiasts can prove invaluable later on.

Can I Teach Myself to TIG Weld?

You shouldn’t try to learn TIG on your own. If you want to excel at performing complex tasks, you’ll need proper guidance. Having a teacher available would aid in achieving greater proficiency.

Sadly, a lot of welding programs have been either reduced in size or eliminated entirely. The good news is that several community institutions still offer introductory courses, allowing you to quickly grasp the fundamentals.

Teaching oneself can actually hinder progress and increase frustration levels rather than help with self-development. Below are reasons why expert assistance is necessary for mastering the art of TIG welding.

1. For Complex Techniques, Expert Instruction Is Better

The majority of TIG welding jobs involve applying the technique to complicated shapes and designs. Trying to figure everything out on your own can hamper production rates considerably.

Due to a lack of experience and improper setup, students will encounter difficulties when attempting to execute advanced moves.

2. On-The-Job Training Improves Accuracy

Without direct supervision, errors can occur. Mistakes made are likely to affect quality, whereas an experienced teacher can spot trouble spots before they escalate into bigger problems. He/she can point out incorrect actions or positions and correct them immediately.

3. Knowing What’s Coming Next Can Help Avoid Confusion or Errors

It’s natural to become confused when faced with unfamiliar terms or words. Oftentimes, students will forget exactly what they did last week or months ago. Having a knowledgeable person explain terminology and processes can save countless hours spent pondering over confusing details.

4. Practicing Correct Posture Helps Improve Eye-Handed Coordination

Poorly executed movements can negatively impact your overall performance. By maintaining correct posture and setting your physical boundaries, you can ensure that your job duties remain safe and productive.

5. Achieving Specific Milestones Effectively Promotes Self-Motivation

Being held accountable for reaching targets increases motivation. A pro will typically set milestones based on the individual’s past achievements. When he or she accomplishes goals, they’re given encouragement and praise.

6. Develop Good Work Habits Through Proper Guidance

Getting accustomed to consistently executing routines improves efficiency. By following directions precisely, students can develop positive habits that carry over into everyday life outside of work.

7. Gaining Knowledge of Safety Procedures Increases Protection Levels Against Accidents

Having a certified teaching partner present ensures that the workplace stays free from injury risks.

8. Instructor Feedback Enhances Problem Solving Skills

Working alongside your trainer will allow you to solve problems quickly and efficiently. They can observe your behavior firsthand and evaluate how effectively you handle setbacks.

9. Personal Attention Builds Long-Term Interest in Subjects

Unlike textbooks, a live trainer will be more invested in your success. Their desire to ensure that you are succeeding increases motivation and ensures that you’re learning the material in an effective manner.

One of the most rewarding aspects of working with a trainer is that they care about your education and development. Your personal trainer will not only ensure that you receive the best training, but also that you enjoy yourself while doing so.

The Bottom Line

The hardest welding method may or may not be TIG, depending on the individual. People may find TIG welding to be considerably simpler than stick welding, and vice versa. The manner you prefer to do things affects how various welding skill sets are perceived. TIG, in my opinion, was the trickiest to master.

Numerous variables are involved in the most finite TIG welding process. Unlike with a MIG machine, you can’t immediately pull the trigger and start cutting. As a result, it moves more slowly and calls for greater caution, organization, and endurance.

TIG is a method that can result in some of the most striking welds. Clients will pay top dollar for TIG welded objects because it truly is an art form. Professional fabricators who work on high-end cars, interior trim, etc., choose it as their method of choice.

Exercise patience and perseverance. Make sure to make the most of your time in the TIG lab if you are a welding student; it will pay off in the long run.

Darell is a Certified Welding Engineer (CWEng) with over 23 years of expertise in TIG, MIG, MAG, dual flux, and stick welding. He is a senior welding engineer who has a desire to share his experience. Visit unwelded.com and join Darell as well as other welding enthusiasts in obtaining fabrication knowledge, amazing welding gadgets, and useful welding insights.