Remember the first time you saw a welder?

I’m sure you were wondering why someone was wearing a helmet and holding a torch. Well, it’s not because they were going to perform a magic trick or set something on fire. Although that would be fun, wouldn’t it? Definitely not.

Of course, those pieces of equipment are used for something that is both fascinating and dangerous: welding.

Welding is an essential skill for many industries and professions, and it can also be a rewarding hobby and a form of artistic expression.

But welding is not without its risks. In fact, welding can be very hazardous if not done properly and safely. It can cause burns, electric shocks, eye injuries, respiratory problems, and even cancer.

According to the Occupational Safety and Health Administration (OSHA), more than 500,000 workers involved in welding activities in the United States alone, risk suffering injuries related to welding each year. Consequently, the Bureau of Labor Statistics recorded 43 welding-related deaths in 2021. Therefore, it’s important to know the risks of welding and how to prevent them.

In this article, I’m going to analyze the main hazards of welding and how to avoid them. I’ll also share some of the best practices and tips that I’ve learned from my experience as a welder and a researcher.

So buckle up, put on your safety glasses, and get ready for a hot and sparkly ride. Because we’re about to dive into what could go wrong with welding.

Are you ready? Let’s go!

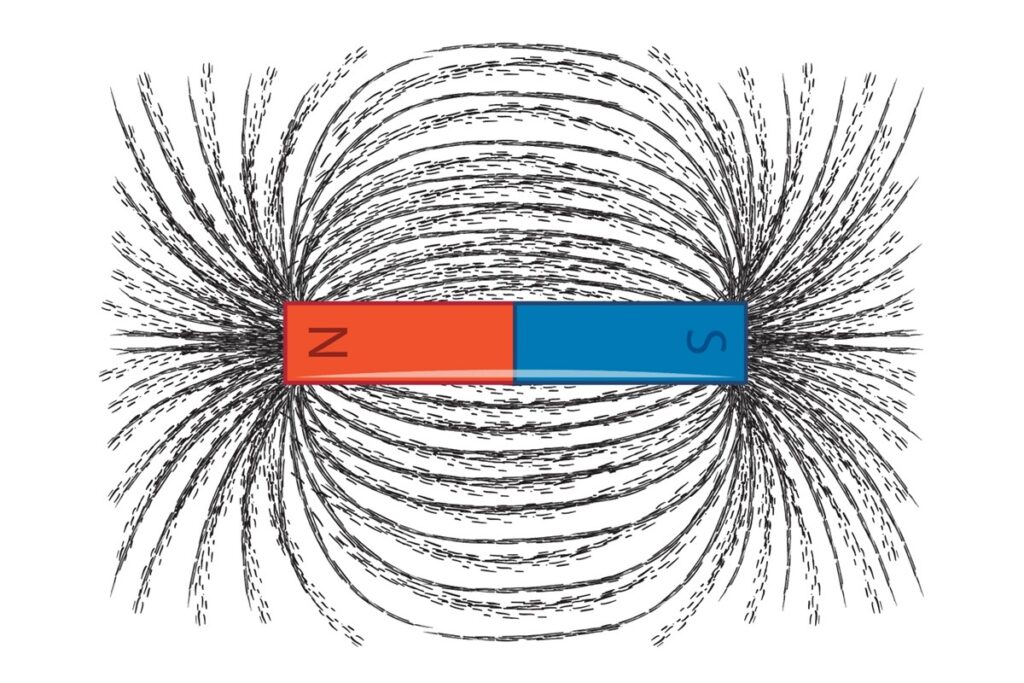

Let’s start with electro-magnetic fields, or EMFs for short.

1. Electro-Magnetic Fields

EMFs are invisible forces that surround electrical devices and wires. They can interfere with the functioning of pacemakers, implantable defibrillators, and other medical devices.

They can also cause headaches, nausea, fatigue, and other health problems. Now imagine what happens when you’re welding near a high-voltage power line, a transformer, or a generator. You’re exposing yourself to a very high level of EMFs that can damage your body or your equipment.

How EMFs Can Kill You

For instance, if you’re wearing a pacemaker or you weld near a power line, you could experience irregular heartbeats or cardiac arrest. Or if you’re using an arc welder and you touch a live wire, you could get electrocuted or start a fire.

So how can you reduce the risk of EMFs while welding?

How You Can Prevent the Risk of EMFs

Here are some tips and best practices:

Moving on to robot accidents.

2. Robot Accidents

Robots are becoming more common in the welding industry as they can perform faster, more accurately, and more complex tasks than humans.

However, robots also pose a risk of injury or death to welders who work with them or near them. Robots can malfunction, misinterpret commands, or collide with humans or objects.

How Robot Accidents Can Be Dangerous

For example, if you’re programming a robot to weld a certain part and you forget to turn off its power supply, it could start welding while you’re still in its path. Or if you’re working on a different part and a robot swings its arm without warning, it could hit you with its torch or clamp.

So how can you mitigate the risk of robot accidents while welding?

How to Avoid Robot Accidents

Here are some safety guidelines:

Now, let’s talk about suffocation.

3. Suffocation

What is suffocation, and how does it pose a risk while welding? Suffocation is the state of being deprived of oxygen, which can result in unconsciousness or death.

How Can Suffocation Happen?

Suffocation can occur while welding in two ways: by inhaling inert gases that displace the air in your lungs or by working in confined spaces that have low oxygen levels. Inert gases such as argon, carbon dioxide, nitrogen, and helium are commonly used in welding to prevent weld oxidation or reduce the risk of fire.

However, these gases can also fill up the spaces where you are working and reduce the amount of oxygen available for breathing. This can happen even in places where you don’t expect it, such as vehicle inspection pits.

Confined spaces such as tanks, pipes, and pits can also have low oxygen levels due to chemical reactions or a lack of ventilation. Working in these locations is dangerous because you may not notice the symptoms of suffocation until it is too late.

Some Real-World Scenarios

So what are some scenarios that could lead to suffocation with fatal consequences while welding? Here are a few examples:

Pipe Welding

Imagine a welder is working on a pipe that is filled with argon gas. He forgets to turn off the gas supply when he finishes welding and leaves the pipe. The argon gas leaks out of the pipe and fills the room where he is working. He returns to the room after a few minutes and collapses due to a lack of oxygen.

Inside a Tank

Or let’s say a welder is working inside a tank that has been cleaned with a chemical solution. The chemical solution reacts with the metal and produces carbon dioxide gas.

The welder does not wear a respirator or use ventilation equipment. He becomes dizzy and confused due to carbon dioxide poisoning and suffocates inside the tank.

Welding In a Pit

Lastly, picture a welder is working in a pit that has a cover on top. He uses nitrogen gas to purge the air from the pit before welding.

He does not monitor the oxygen level inside the pit or use a lifeline to communicate with his co-workers. Gradually, he loses consciousness due to nitrogen asphyxiation and dies before anyone notices.

These scenarios may sound extreme, but they are based on real-life cases that have happened in the past.

How can we prevent them from happening again?

How to Reduce the Risk of Suffocation

Here are some tips and best practices for reducing the risk of suffocation while welding:

Be aware of the symptoms of suffocation, such as headache, nausea, drowsiness, weakness, confusion, and loss of coordination. If you experience any of these symptoms, stop working immediately and seek fresh air.

How about radioactivity, how does it pose a risk while welding?

4. Radioactivity

Radioactivity is the process of atoms breaking down and releasing energy and particles, such as alpha, beta, and gamma rays.

This can pose a risk while welding because some metals or materials may contain radioactive elements or contaminants that can emit radiation when heated or cut.

Exposure to radiation can damage the cells and DNA of the body, leading to cancer, mutations, or other diseases.

What are some scenarios that could cause radioactivity with fatal consequences while welding?

Situations That Can Expose You to Radioactivity

Secondhand Radiation

One scenario is welding on pipes or tanks that have been used to transport or store radioactive substances, such as nuclear waste or fuel.

If the welder is not aware of the history of the equipment or does not use proper protective measures, they may be exposed to high levels of radiation that can be lethal.

Welding Irradiated Metals

Here is another example. Imagine welding metals that have been irradiated for sterilization or testing purposes, such as medical devices or aerospace components.

These metals may retain some residual radioactivity that can be released during welding. The welder may not know that the metal has been irradiated or may not follow the appropriate safety procedures for handling it.

Welding on Scrap Metal

A third instance is welding on scrap metal that has been contaminated with radioactive sources, such as smoke detectors, industrial gauges, or military equipment.

These sources may be hidden inside the metal or mixed with other metals and may not be detected by visual inspection or standard radiation monitors. The welder may unknowingly expose themselves and others to dangerous levels of radiation.

Some Ways to Reduce the Risk of Radioactivity While Welding

Assuming the chances of being exposed to radioactivity was not bad enough, here comes explosion.

5. Explosion and Fire Outbreak

An explosion is a sudden release of energy that causes a loud noise and a shock wave. It can occur when a flammable gas or vapor is ignited by a source of heat or spark. This can cause severe injuries or death to anyone nearby, as well as damage to property and equipment.

How Can an Explosion and Fire Outbreak Occur While Welding?

There are several possible scenarios that could lead to an explosion while welding. Some of them are:

Welding Near Inflammables

Let’s say you are welding near or on containers that hold flammable liquids or gases, such as fuel tanks, gas cylinders, pipelines, or drums.

I hope not though because if the container is not properly emptied, cleaned, vented, or purged before welding, the heat or sparks from the welding arc could ignite the flammable contents inside the container and cause an explosion.

Or perhaps one is welding near or on materials that have been coated or treated with flammable substances, such as paint, oil, grease, solvents, or anti-corrosion agents. If these substances are not removed or covered before welding, they could catch fire or vaporize and form explosive mixtures with air.

Welding in Confined Spaces

Even so, welding in confined spaces that have poor ventilation or oxygen deficiency If there is not enough fresh air in the space, the welding gases such as argon, carbon dioxide, nitrogen, or helium could displace the oxygen and create an asphyxiation hazard.

Moreover, if there are any flammable vapors or dust present in the space, they could accumulate and form explosive atmospheres that could be ignited by the welding arc.

Welding With Incorrect Settings or Equipment

Furthermore, welding with incorrect settings or equipment that causes excessive spatter or arc instability If the voltage is too low or the amperage is too high for the welding wire and gas combination, it could result in a stubbing effect that produces popping sounds and spatter.

This spatter could land on flammable materials or surfaces and start a fire or an explosion.

How To Minimize Risk of Explosion and Fire Outbreak

Here are ways for preventing explosions while welding:

Now, let’s talk about fume poisoning, and how it does pose a risk during a weld work.

6. Fume Poisoning

Fume poisoning is a condition that occurs when you inhale or ingest harmful substances that affect your health.

While welding, you may be exposed to various toxic substances that are produced as byproducts of the welding process, such as metal fumes, gases, dust, and vapors.

Some of these substances include zinc oxide, aluminum oxide, magnesium oxide, lead, cadmium, chromium, nickel, arsenic, manganese, beryllium, cobalt, selenium, and zinc.

These substances can cause various acute and chronic effects on your respiratory system, nervous system, skin, eyes, kidneys, liver, blood, and reproductive system.

Some Fumes Can Kill You

Metal Fume Fever

One of the most common and serious forms of poisoning among welders is “metal fume fever.” This is an illness caused by exposure to zinc oxide fumes that are generated when welding galvanized steel or other metals containing zinc.

Metal fume fever causes flu-like symptoms such as fever, chills, nausea, headache, fatigue, muscle aches, joint pains, lack of appetite, shortness of breath, pneumonia, chest pain, and coughing.

In severe cases, metal fume fever can lead to shock, no urine output, collapse, convulsions, cardiac arrest, and death.

Cadmium Fumes

Another form of poisoning that can be fatal is exposure to cadmium fumes. Cadmium is a metal that is present in some older silver solder alloys and some anti-corrosion paints.

Cadmium fumes can cause severe lung damage and kidney failure. They can also cause loss of consciousness and death within minutes of exposure.

Manganese Fumes

A third example of poisoning that can be deadly is exposure to manganese fumes. Manganese is an essential element that is found in many metals used for welding.

However, excessive exposure to manganese fumes can cause neurological damage and a Parkinson-like syndrome known as manganism.

Manganism causes symptoms such as tremors, slowness of movement, muscle rigidity, poor balance, mood changes, memory loss, altered reaction time, and reduced hand-eye coordination.

It can also affect the reproductive system and cause infertility in men. In extreme cases, Manganism can lead to respiratory failure and death.

Helpful Tips To Lower the Risk of Fume Poisoning

The best way to prevent fume poisoning while welding is to avoid exposure to toxic substances as much as possible. This can be done by following these steps:

Earlier, we considered how dangerous radioactivity can be. This time, we will discuss something similar: optical radiation.

7. Optical Radiation

Optical radiation is a form of electromagnetic radiation that includes ultraviolet (UV), visible, and infrared (IR) light.

Welding arcs produce intense optical radiation that can damage your eyes and skin. UV radiation can cause sunburn, skin cancer, eye inflammation, cataracts, and welder’s flash.

Be that as it may, visible light can cause glare, eye strain, and reduced vision. IR radiation can cause heat stress, burns, and eye damage.

What to Look Out For

Welder’s Flash or Arc Eye

One of the most common and serious effects of optical radiation while welding is the welder’s flash or arc eye. This is a painful condition that occurs when the cornea of the eye is burned by UV radiation from the welding arc.

Welder’s flash causes symptoms such as redness, swelling, tearing, sensitivity to light, blurred vision, and a feeling of sand in the eye. In severe cases, a welder’s flash can lead to permanent vision loss or blindness.

High-Intensity Visible Light

Exposure to high-intensity visible light from the welding arc can cause temporary or permanent blindness due to retinal damage or macular degeneration.

High-Intensity IR Radiation

A third instance that could cause optical radiation with fatal consequences while welding is exposure to high-intensity IR radiation from the welding arc or the molten metal. This can cause severe burns to the skin and eyes that may require skin grafts or surgery.

How may the risk of optical radiation during welding be reduced? And what are some recommended practices?

Practical Advice to Reduce Optical Radiation Risk

The best way to prevent optical radiation while welding is to shield your eyes and skin from the welding arc and its reflection. This can be done by following these steps:

8. Electrocution or Electric Shock

Electric shock is the passage of electric current through the body. It can cause pain, burns, muscle spasms, cardiac arrest, and even death.

Electrocution is a common hazard for welders because they work with high-voltage equipment and metal objects that can conduct electricity.

Can You Electrocute Yourself When Welding?

The answer is yes. There are many scenarios that could lead to an electric shock while welding, such as:

Any of these situations could result in a fatal electric shock if not handled properly.

How to Prevent Electric Shock While Welding

Here are some pointers and suggested actions:

You can lessen your chance of electric shock while welding and shield yourself from severe harm by adhering to these best practices and suggestions.

Now let’s move on to cancer.

9. Cancer

Cancer is a group of diseases that involve abnormal cell growth that can invade or spread to other parts of the body.

This pose a serious health risk for welders because they are exposed to dangerous fumes and gases that contain carcinogenic substances.

These substances can enter the body through inhalation, ingestion, or skin contact and cause damage to the DNA of cells.

Substances That Can Cause Cancer While Welding

Some of the substances that can cause cancer while welding are:

How Can Welding Cause Cancer?

There are numerous circumstances in which welding could result in cancer, including:

Any of these situations could increase your exposure to carcinogenic substances while welding and increase your risk of developing cancer later in life.

What Can You Do to Prevent Cancer When Welding?

So how can you prevent cancer while welding? See some helpful tips below:

The Bottom Line

And that, my friends, is the end of our journey into the dark side of welding.

We have covered a lot of ground today, from the potential hazards and health effects of welding exposure to the best practices and preventive measures to reduce the risks and enhance the safety and quality of your work.

As you can see, welding is not a simple or easy profession. It requires a lot of skill, knowledge, and attention to detail. It also involves a lot of responsibility, not only for yourself but also for your co-workers, your clients, and the environment.

I don’t want you to leave this page feeling scared or discouraged. That’s not the purpose of this article. My goal is to provide you with an in-depth risk analysis of the welding profession based on scientific evidence and personal experience.

This is to enable you to make informed decisions and take appropriate actions.

So what can you do? Well, the first thing you can do is start implementing the best practices that we discussed today. Follow the guidelines and standards that are established by reputable organizations and authorities.

But that’s not all. You can do more than that. Educate yourself and others about welding safety. Share your knowledge and experience with your colleagues and peers. In other words, you can be part of the solution. Don’t you agree?

Thank you for your attention and happy welding!

Darell is a Certified Welding Engineer (CWEng) with over 23 years of expertise in TIG, MIG, MAG, dual flux, and stick welding. He is a senior welding engineer who has a desire to share his experience. Visit unwelded.com and join Darell as well as other welding enthusiasts in obtaining fabrication knowledge, amazing welding gadgets, and useful welding insights.