When you’re working on electronics projects and making your first circuit boards, there are two tools that will come in handy more than any other: the rework station (or “desolder” as my son calls it) and the soldering station.

In this article, we’ll take a look at these devices and what they do to help you better understand their use.

The ideal device for working with fragile components is a rework station. It enables simple desoldering and modification without much risk of part damage. Rework stations, however, are more pricey, inconvenient, and imprecise than soldering stations.

- What Is a Rework Station?

- Advantages of a Rework Station

- Disadvantages of a Rework Station

- What Is a Soldering Station?

- Advantages of a Soldering Station

- Disadvantages of a Soldering Station

- Differences Between Rework Stations and Soldering Stations

- What Is a Soldering Iron?

- What Is a Soldering Gun?

- Things to Keep in Mind

- The Bottom Line

Desoldering, or removing unwanted wires from around an integrated chip, can be a tricky business. The best way to get rid of them is by using a desoldering pump with heat-activated suction, but it’s not always practical because some chips need special attention.

And even if you have a good old wire stripper, sometimes the connections just keep breaking during removal. That’s where the hot air gun comes into play. It removes stubborn solder joints without damaging anything underneath.

But before going over how each one works, let’s start with the basics: What is a rework station?

What Is a Rework Station?

The term “rework” means taking apart something that was previously assembled, replacing/repairing subcomponents, etc.

There are several ways to perform reworks, including mechanical methods like prying off pieces of circuits with pliers and using chemical solvents like acetone, rubbing alcohol, ether, ammonia, freon, benzene, and others.

You can also use thermal methods such as heating up the joint until the solder liquefies enough so it can simply be wiped away.

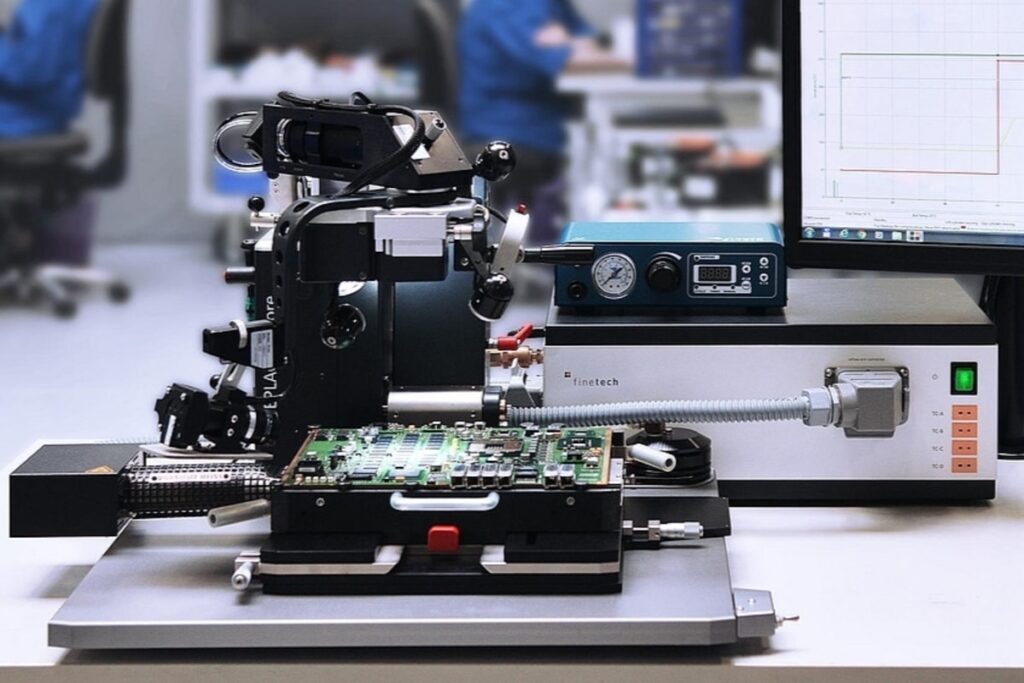

When people refer to a rework station, they usually mean the latter—a table specifically made with holes drilled all over its top surface. It can be used to desolder or solder electronic components.

Use Cases

These stations allow users to quickly remove tiny wires and solder pads without having to worry about getting their hands dirty.

They also serve as workbenches because most include additional features like drawers, hooks, storage bins, and shelves. Some models even feature built-in power strips and USB ports!

While a rework station is useful when dealing with standard-sized integrated circuits, there are times when you may want to deal with larger items like connectors and printed circuit board assemblies.

For these situations, you should check out our guide detailing how to disassemble PC cases safely and easily.

Advantages of a Rework Station

As mentioned earlier, reworking small items is pretty straightforward. But once you move on to bigger ones, the process gets much harder since you don’t know which area needs to be removed and which stays put. This is where a rework station really shines.

1. Provides Support for the Item Being Worked

By providing support for the item being worked on while keeping everything else steady, it allows you to focus solely on the component you wish to remove. Once you’ve got the target part isolated, it becomes much easier to scrape away the excess material.

You might think that using heavy scrapers would damage the object, but you’d be surprised. Those things aren’t meant to cut through metal, only provide pressure against it.

2. Keeps Everything Contained Within Its Boundaries

Another advantage of a rework station is that it keeps everything contained within its boundaries, meaning no spills or wasted materials.

If you were doing a large job yourself, you’d probably end up accidentally contaminating areas you didn’t intend to touch.

Not to mention that this could potentially cause harm to someone who follows after you later. With a rework station, however, nothing goes outside its housing unless it has been properly disposed of.

Plus, it provides easy access to all the necessary supplies and tools, allowing you to complete jobs faster and safer.

Disadvantages of a Rework Station

There are some drawbacks associated with using a rework station.

1. Can’t Be Easily Moved Around

Chief among them is the fact that it doesn’t offer very high mobility. Because it’s bolted down, you can’t roll it around wherever you see fit. Due to its design, it isn’t particularly portable either.

2. It’s Large in Size

Its footprint makes it difficult to squeeze into tight spaces, especially cramped desks. Lastly, depending on the model, they may require extra space behind it to prevent accidental knocking objects inside. All these factors make it hard to pull off quick tasks away from home.

Now that you know what a rework station is, let’s talk about another important topic: soldering.

What Is a Soldering Station?

If you’re familiar with the concept of soldering, then you already know what a soldering station does.

Basically, it serves as a workspace for applying heat to various types of electronic components. To achieve this task, the station includes multiple adjustable legs that can raise or lower themselves based on the height needed.

Use Cases

After placing the targeted component on the platform, the user adjusts the legs accordingly to create a stable base for further operations.

Then he uses a heated tip attached to a hose to apply sufficient amounts of electricity to melt the solder between the leads of the item. Finally, he wipes away the melted solder with a soft cloth to reveal cleanly joined electrical terminals.

Like a rework station, a soldering station offers similar advantages. One major benefit of using one is that it prevents spillage and waste. Another is that it frees up precious desk space since you won’t have room for both equipment anymore.

Third, unlike a rework station, it’s extremely mobile. Most models fold flat, which makes them perfect to carry anywhere. And lastly, it creates less mess since you won’t find stray bits of molten lead floating in the air.

Advantages of a Soldering Station

Aside from the obvious benefits of efficiency and safety, soldering stations also bring a few unique perks to the table.

1. You Can Easily Control the Temperature

First, it lets you control temperature settings via remote controls instead of relying on manual knobs.

2. Produces Fewer Fumes

Second, compared to regular iron tips, soldering guns produce far fewer fumes.

3. Offers Great Precision

And third, it gives you greater precision in positioning the leads. Since the whole thing happens automatically, you don’t have to worry about wasting time fiddling with different positions and angles.

Disadvantages of a Soldering Station

However, despite the positives, there are still some flaws to consider.

1. Takes Practice to Master Proper Soldering Techniques

Basically, it takes practice to master proper soldering techniques. As a result, beginners often prefer learning soldering separately rather than buying a dedicated unit.

2. Quality Soldering Machines Are Expensive

Additionally, it requires quite a bit of money to purchase a quality soldering machine, although cheaper options exist too. Last but certainly not least, it costs quite a lot of cash to upgrade from single-tip machines to multi-tip units.

Now that you know what soldering stations are, let’s talk about their counterparts, soldering irons.

Differences Between Rework Stations and Soldering Stations

The differences between the Rework Station and the Soldering Station are subtle. For one, a rework station does not offer the same level of control over temperature as a soldering station.

Since it doesn’t have a heating element, it cannot heat up your components for an exact amount of time. And since you cannot set it to heat up more slowly, you will have to deal with longer work times.

Another difference is that rework stations are much more expensive than soldering stations. They cost between $75 and $150, whereas the soldering station can go as low as $50.

Furthermore, soldering stations are much better in terms of precision and temperature control than rework stations.

What Is a Soldering Iron?

If you’ve used a soldering iron before, then you know what one does. Basically, it consists of a pair of metal prongs with tips attached to them.

To heat the tips up, the user connects an electric cord and switches on the power source. Then he inserts one or both prongs into the component in question. After placing the tips on the lead’s ends, he presses down to create an electrical connection.

Benefits of Using a Soldering Iron

Although a soldering iron does share similarities with a soldering station, it still has its own set of benefits. One major benefit is that it lets you connect wires and components quickly and easily.

A second one is that it’s less messy than a soldering station since it uses less heat for melting the solder instead of heating up the entire thing via electricity. And lastly, it can be used for most electronics, like the ones you find in your home.

As you can see, soldering stations and irons have their benefits and downsides. Ultimately, it’s up to you to decide what type of equipment you need for your needs.

But as a general rule, we recommend that you go with a soldering station if possible because it does so many things at once. Not only does it offer more control and precision over temperature settings, but it also makes sure that your work doesn’t get contaminated or burned.

What Is a Soldering Gun?

A soldering gun is a combination of a soldering station and a soldering iron. They offer the same benefits as both products but with more precision in positioning and temperature control.

Like a soldering station, it consists of two metal prongs that are connected to the power source. But instead of having an electric cord that connects to them, it comes with its own handle for easier operation.

When used in conjunction with an iron, the user simply slides the heated tip over the component in question, presses it down, and then removes it.

Since they offer the same benefits as soldering stations, we won’t go over them again. If you want to know more about them, you can check out our article.

Things to Keep in Mind

In conclusion, here are some final considerations to keep in mind when deciding whether you should buy a rework station or a soldering station.

Of course, there are plenty of decisions to be made when choosing which type of station suits your specific needs the best.

Hopefully, though, we were able to shed light on the key differences between the two devices. Now it’s your turn to decide which one fits your budget and lifestyle the best. Good luck!

The Bottom Line

Hopefully, by now, you’ve realized that there are many benefits associated with having both a rework station and a soldering station.

As such, it makes sense to invest in one or the other. As for me, I find that my soldering station does a better job at fixing broken electronics than my rework station does.

Darell is a Certified Welding Engineer (CWEng) with over 23 years of expertise in TIG, MIG, MAG, dual flux, and stick welding. He is a senior welding engineer who has a desire to share his experience. Visit unwelded.com and join Darell as well as other welding enthusiasts in obtaining fabrication knowledge, amazing welding gadgets, and useful welding insights.